We believe that an awesome performance requires an equally epic medal, and so, as you’d expect, a Global Marathon Challenge medal is not your average, run-of-the-mill, 80 or 90mm circular medal dangling from a bit of old rope!

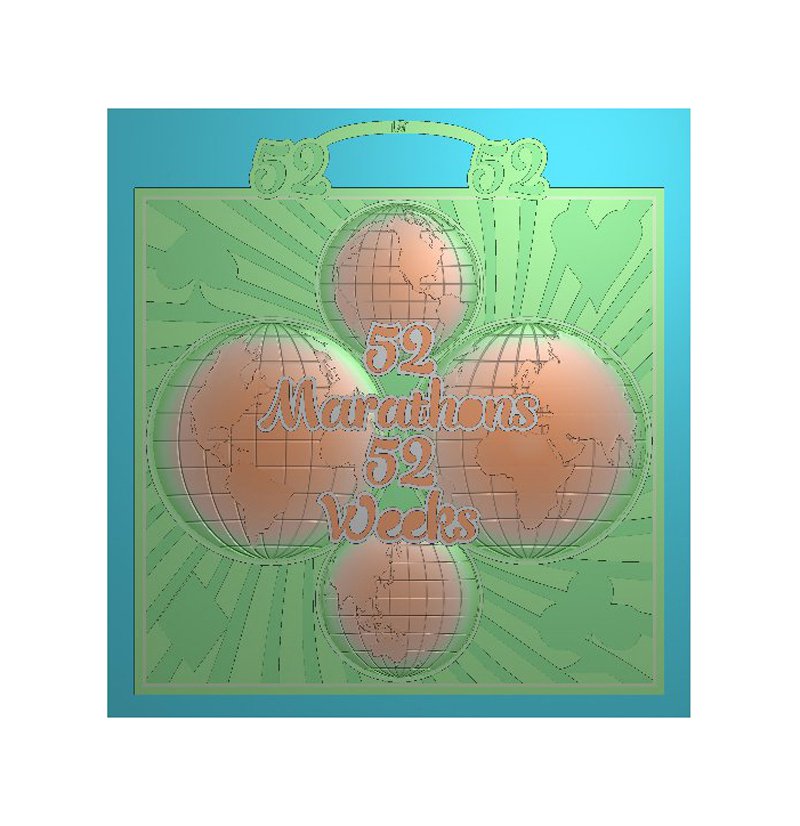

First, we went through the design phase – not as straight forward as you might think. All our medals start with an idea which then gets sketched out, the old fashioned way, using pencil and paper. Then we work with our design partners to bring that initial sketch and theme to life in a 2-dimensional format. The first medal in the GMC stable was the awesome 52 Marathons in 52 Weeks and this went through no fewer than 14 design versions just to get the shape / size / lines / layout and basic design done. It’s during this initial design phase that the medals evolve and change the most; heads are scratched, ideas come and go and a pile of screwed up paper builds up next to the waste paper basket.

Did you know? All our GMC medals are 152mm wide because of our original 52in52 marathon challenge medal – just because, somehow, 150mm didn’t seem quite big enough.

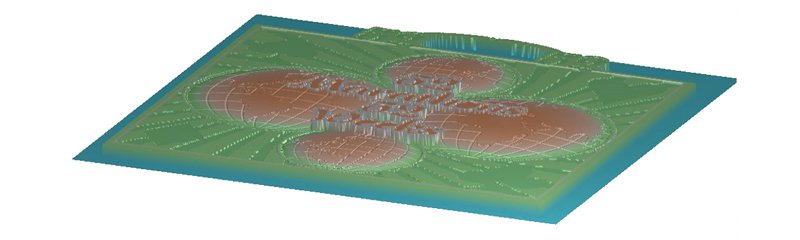

Next the design vector files are turned into 3 dimensional images. This gives us a real feel for the true size and depth of the medals. The marathon medals are a whopping 10mm, that’s 1 cm, thick and it’s hard to get a good idea of the scale of that in a flat drawing. The globes are raised into 5.5mm domes with a two-tone gold / coloured and glittered finish. The 3D images enable us to see what these effects are going to look like and are then used to create the medal die or mould.

Did you know? Most ‘standard’ medals produced don’t have a 3D imaging stage at all in their production. We use 3D Imaging, well, mostly just because it’s really cool.

Casting the medal mould is one of the most important stages in production and needs to be right. Any error or blemish that goes unnoticed at this stage will appear on every, single, medal. Up until this point changes can still be made without too much difficulty, but once the mould is made, whilst it’s not impossible, changes are very difficult and expensive.

Did you know? When the first 12in12 pre-production medal was sent to us for inspection we noticed that the border around the text was half a millimetre too broad. We just couldn’t ignore this, so rather than accept an inconsistency; we had the entire mould remade from scratch.

The medals are then manufactured from the mould which is done mechanically and the raw medals or ‘blanks’ are created. These look pretty plain and dull at this stage.

Did you know? Our medals are made from a combination of 10 different metals – predominantly zinc with aluminium, cadmium, copper, iron, magnesium, lead, tin, nickel and even silicone (which is a metalloid).

This is the part of the process that decides what overall ‘finish’ your medal will be; antique bronze, antique gold, brass, pewter, nickel, the list goes on. There are around 15 main plating options but in reality this is almost infinite if you know what you want and can push the manufacturers hard enough. All GMC medals are plated in an antique silver / pewter finish.

Finally the colours and enamelling are added and then lastly the whole medal is polished. During this stage in the production of the 100in100 medals we added a glitter to our enamelling to give it even more depth and sparkle.

Did you know? From the raw production or ‘blank’ stage onwards, all our medals are hand plated and hand finished. This means that no two medals are exactly the same and each one comes with its very own uniqueness, characteristics, blemishes and all; giving your medal its very own individuality.

Often overlooked or a mere afterthought, this is not the case at Global Marathon Challenges. Our ribbons form an integral part of our medals, right from the first design stage, and our ribbons have been known to go through up to 10 design versions of their very own before reaching sign-off. The ribbons are carefully designed to give continuity to our medals and often form an ‘extension’ of the medal design itself. All GMC ribbons are full colour, heat-transfer; a superior form of ribbon production, which allows us to place absolutely any design onto our ribbons. We use only 38mm wide ribbons at 812.5mm long to give the perfect fit.

Did you know? We have extra stitching on our GMC medal ribbons because these need to be super-strong. The medals weigh in at over 800grams each, so you wouldn’t want to drop one on your foot!